GearTopper: Linear actuators

In this monthly recurring column we would like to put a transmission or related product into the spotlight, our GearTopper. In this way, we like to share our product knowledge with our readers. This edition we focus on actuators.

Linear actuators are great products to create a linear movement. There are many different kind of linear actuators but they all work on the same principle. They change a rotational movement on the input of the actuator into a linear movement which is created by a trapezoidal screw or ballscrew. The trapezoidal screws are used for lower speeds and lower accuracy where a ballscrew is perfectly suitable for high linear speeds and very accurate positioning.

There are three different executions available in the market:

- the inline version with the input shaft inline with the extension rod

- the angular version with the input shaft under a 90 degrees angle

- the parallel version with the input shaft parallel with the extension rod

A linear actuator is a well protected version of a screw jack. The screw and nut are fully integrated in the unit and between the housing and extension rod there is a seal to protect the inside against water and dirt from the environment.

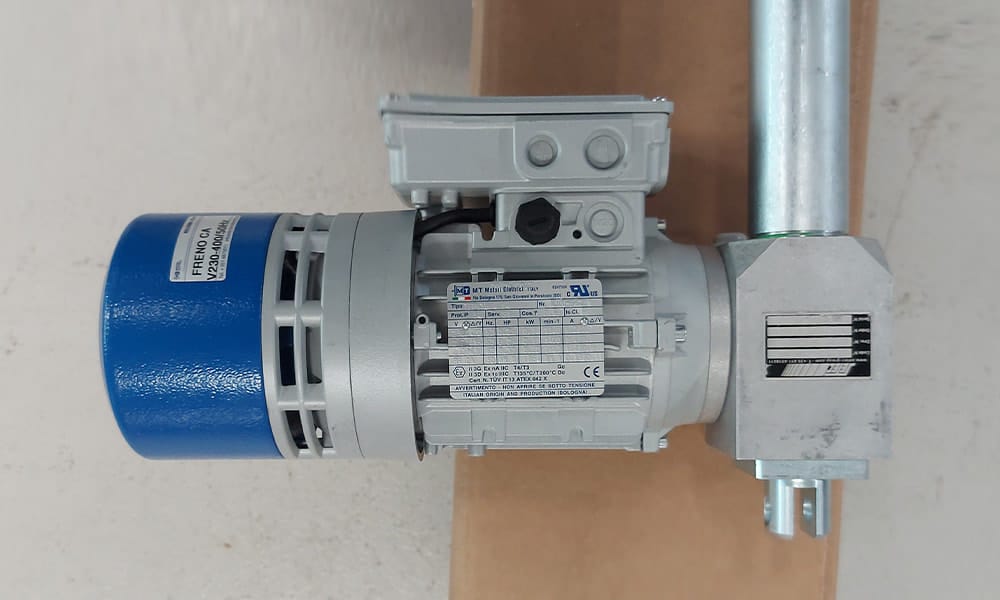

The actuator is mostly driven with AC or DC motor, servomotor or sometimes even manually. Between the electric motor and actuator there is sometimes used a small (planetary) gearbox to reduce the motor speed compared to the screw speed. To mount the actuator in a machine there are several options, mainly depending on the use and application. Next to that several options are available like fixed or adjustable limit switches, anti-rotation, encoder, second shaft end etc.